Our Technology

Performance

The Spool Compressor is an effective ZERO GWP solution across a range of applications and refrigerants. Current development is focused on commercial air conditioning, including air-cooled chillers, water-cooled chillers, and rooftop units, with compressor capacities between 20 and 60 TonsR.

Torad is currently testing a 20 TonR compressor operating on Solstice® ze. Operating at the standard ARI 45°F/130°F flange conditions, at 1800 RPM, with power measured at the motor terminals, this compressor achieves an overall isentropic efficiency of 72.5. The EER is 12.2 (COP – 3.58). Thus, the Torad spool compressors efficiency is 4% to 9% better than any compressor in this size range operating on Solstice® ze.

This spool compressor is designed for use at high ambient conditions reaching a maximum condensing temperature of 170℉. It will also accommodate low pressure ratio applications such as data center cooling with high efficiency. This is made possible by automatic discharge valves that adapt to changing operating conditions.

See the Future Now.

TORAD’s spool compressor is viable across a broad range of applications. TORAD’s current focus is on commercial air-conditioning between 7.5 tonR (22 kW) and 100 tonR (350 kW).

The spool compressor shares attributes with rotary, sliding vane and rolling piston compressors with improvements that allow it to overcome limitations of the legacy technologies.

These improvements allow the spool compressor to scale into larger capacities, achieve higher efficiencies while maintaining a simple design and low manufacturing cost. The spool compressor has only one major moving assembly, a rotor mounted eccentrically to a housing.

Three key improvements from legacy rotary compressors:

ONE

A sliding vane is constrained by means of a patented eccentric cam. This controls the vane tip to be held in close proximity to the cylinder bore while never contacting the bore reducing friction, wear and power, improving performance.

TWO

The vane is sealed to the bore via a tip seal which is configurable to be balanced, exerting adequate force on the bore to seal the process, generating only minimum friction.

THREE

The rotor has affixed endplates that rotate with the shaft and vane forming the rotating spool assembly. Dynamic sealing elements between the endplates and cylinder housing minimize leakage between the compressor containment and the process. This allows the machine to scale to larger capacities while maintaining performance and manufacturability.

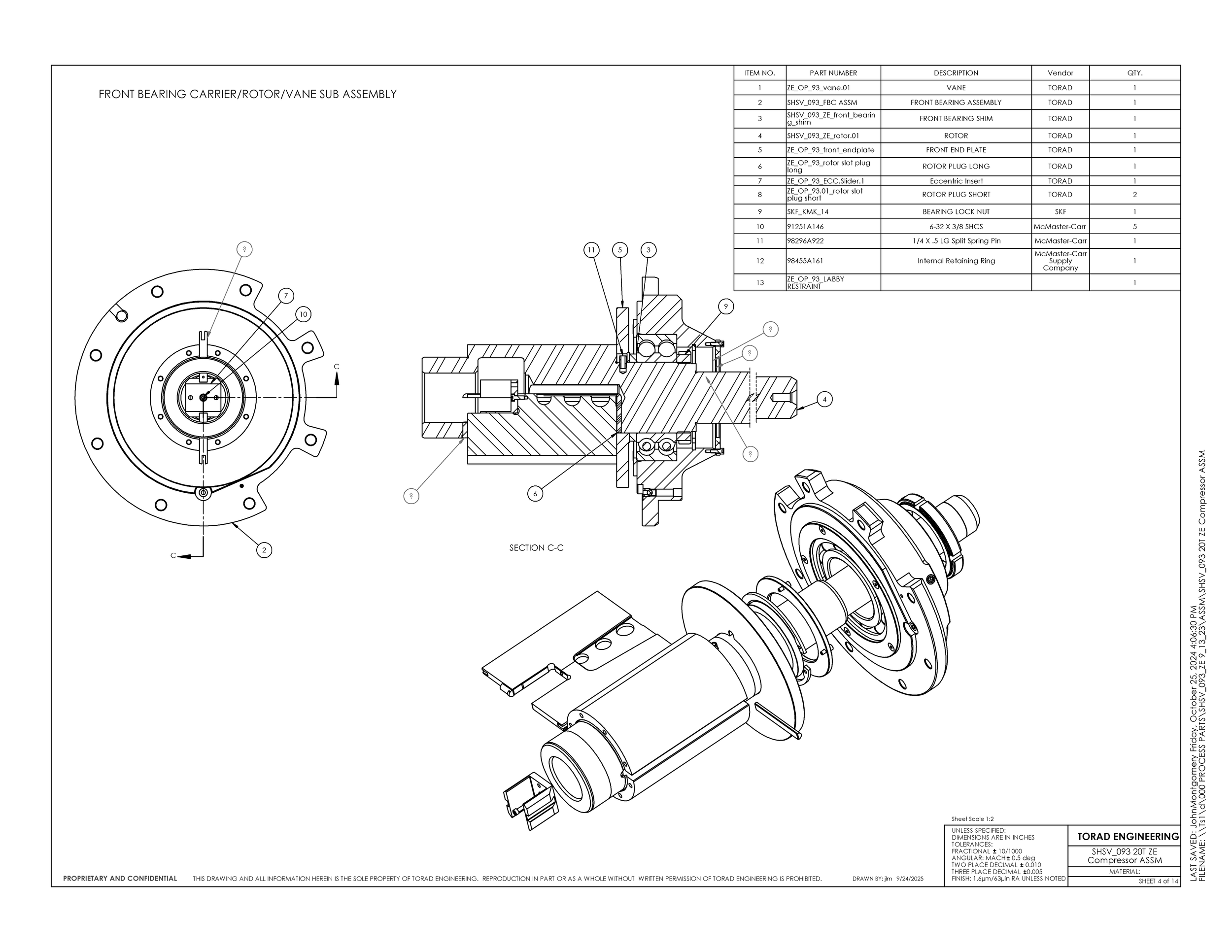

Rotor assembly is shown on left and cylinder housing and bearing assemblies on right.

The spool compressor is a restrained vane device with novel features, providing increased efficiency and the ability to scale to larger capacities. TORAD has been working to minimize manufacturing complexity resulting in a compact design, manufacturable at a low cost when compared to the complex geometry of a screw or scroll compressor. The spool compressor can be configured in an open drive, semi-hermetic or fully hermetic configuration and can be used in vertical and horizontal orientations

Refrigerants

What we see is a market in transition. Today, moving toward HFO/HFC blends with GWPs around 600. Ultimately moving toward mandated GWPs near zero. This points to market adoption of pure HFO refrigerants.

TORAD is working diligently to introduce its technology optimized for zero GWP refrigerant Solstice® ze (R-1234ze). Considering toxicity, ODP, GWP, flammability, cycle efficiency, operating pressures and cost, TORAD believes the spool compressor utilizing Solstice® ze is a future-proof solution. The spool compressor’s architecture is well suited for applications utilizing low density gas due to its high displacement density and low cost to manufacture. Solstice® ze is a low pressure/low density refrigerant. Thus, to achieve the same cooling capacity of an R-410A based compressor the Solstice® ze based compressor flow rate must be increased 2.5 times.

Today we are testing Solstice® ze (R-1234ze) exclusively.

We plan on testing R-513A in the future.

FAQs

-

The compressor is specifically designed for use with heat exchangers at 0 ℉ Suction Super Heat to minimize cost and maximize system efficiency.

The compressor uses a high side oil system that can operate down to 10 ℉ of discharge superheat and requires no oil pump as the oil is circulated by pressure differential. This makes the system insensitive to speed so the application of a VFD does not require any changes to the compressor design.

-

At this time the compressor requires oil for reliable operation. TORAD is exploring a “minimum entrained oil” version..

-

The Spool Compressor is a versatile device applicable to a broad range of applications. At this time development is focused on low pressure/low density HFO refrigerants, however, Torad has designed and tested many compressors:

5 Ton residential compressor for R410a

1 Ton refrigeration compressor using R404a

50 kW waste heat expander utilizing R134a.

5 KW light weight compressor for transportation utilizing Ammonia.

All these machines have been designed, manufactured and tested at Torad’s lab.

-

The spool compressor is compatible with a broad range of refrigerants. TORAD’s recent development focus is on commercial air-conditioning applications with low-GWP refrigerant Solstice® ze (R-1234ze). Please contact TORAD if you have interest in other refrigerants.

-

The spool compressor is easily manufactured on legacy machine tools. There are no components that require 2D or 3D interpolation like the scroll or screw compressor. Additionally, the spool compressor has excellent displacement density. These facts combined result in a lighter weight compressor with lower material cost and reduced cost in feature generation and complex metrology.

-

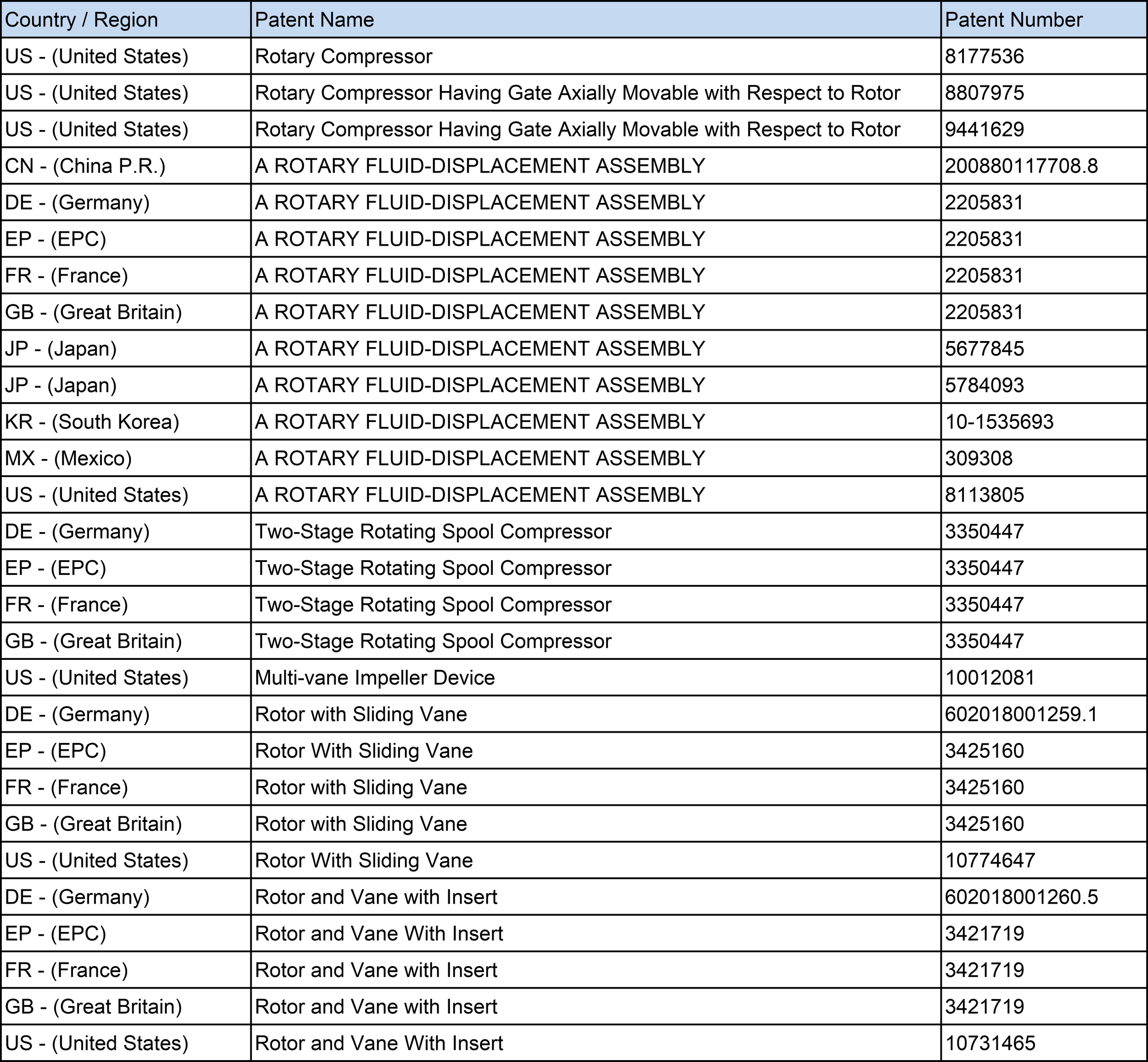

TORAD has multiple utility patents (below) in the US and strategic countries and regions around the world.