TORAD’s Spool Compressor for a Smarter Environmental Future

HISTORY

For the past 10 years, the team at TORAD Engineering in Cumming, Georgia, USA has been developing the next generation refrigerant compressor. Their patented rotary spool machine technology is being designed to enable near zero global warming air-conditioning across a broad range of applications.

SPOOL COMPRESSOR TECHNOLOGY

The rotary spool compressor shares various attributes with legacy rotary compressors, sliding vane and rolling piston. However, the rotary spool compressor has several key improvements allowing the mechanism to overcome the historical limitations of these technologies. These improvements, allow the rotary spool compressor to achieve higher efficiencies and yet maintain the simple design and low manufacturing cost of a rotary machine.

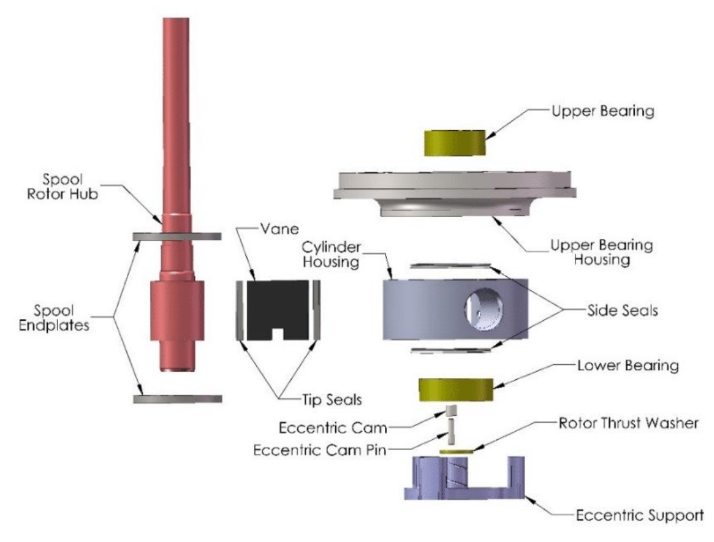

The rotary spool compressor has only one major moving assembly, which is a rotor mounted eccentrically to a housing. An exploded view of the mechanism assembly is shown below.

Rotor assembly is shown on left and cylinder housing and bearing assemblies on right

There are three key improvements from legacy rotary compressors.

⦁ The vane is constrained by means of an eccentric cam allowing the end to be held in close proximity to the cylinder housing bore while never contacting the bore, which eliminates friction and wear.

⦁ The vane is sealed to the bore via a tip seal which is configurable to be well balanced exerting adequate force on the bore to seal the gas, while at the same time generating minimum friction.

⦁ The rotor has affixed endplates that rotate with the central hub and vane forming the rotating spool and uses dynamic sealing elements, between the endplates and cylinder housing, to minimize leakage between the compressor containment and the process pockets.

BENEFITS/FLEXIBILITY

Because the spool machine is a type of restrained vane device with several novel features, this allows increased efficiencies and the ability to scale from small to larger capacities. In addition, TORAD has been working to minimize manufacturing complexities to offer: a simple design; compact size; low part count; low cost; easily configurable; and simple geometry. The spool compressor can be configured in an open drive, semi-hermetic or fully hermetic configuration and can be used in vertical and horizontal orientations.

NEAR-ZERO GWP AIR-CONDITIONING

Torad Engineering is working diligently to introduce its technology optimized on near-zero GWP refrigerant Solstice® ze (R1234ze). Taking into account toxicity, ODP, GWP, flammability, cycle efficiency, operating pressures and cost, TORAD believes the spool compressor utilizing R1234ze from Honeywell is the future-proof solution. The spool compressor’s architecture is well suited for applications utilizing low density gas due to its high displacement density and low cost to manufacture.

TORAD’s spool compressor with R1234ze has achieved EERs within 2.5% of a similarly operating R410A scroll. R1234ze is a low pressure/low density refrigerant. Thus, to achieve the same cooling capacity of an R410A based compressor the R1234ze based compressor flow rate must be increased 2.5 times.

APPLICATIONS/EFFICIENCY

TORAD has design the spool compressor to be flexible for multiple applications. TORAD’s current focus is on commercial air-conditioning between 22 kW (7.5 tonR) and 350 kW (100 tonR). Torad is now testing R1234ze with a 105kW (30 tonR) prototype spool compressor originally designed for use with R134a. No modifications have been made to this R134a prototype to optimize for R1234ze. Preliminary test results show the expected reduction in capacity of 22% (based on the lower density of the gas), but a reduction in overall isentropic efficiency of only 1.8 points at typical air-cooled chiller conditions. TORAD’s technical analysis projects its next generation semi-hermetic compressor designed specifically for Solstice® ze will have favorable EERs.

PRODUCTION

TORAD Engineering plans to produce the compressors independently or through a joint venture. TORAD is currently negotiating license agreements with several OEMs. Limited field samples will be available Q1 of 2020 for partners.

Article reposted with permission from JARN.